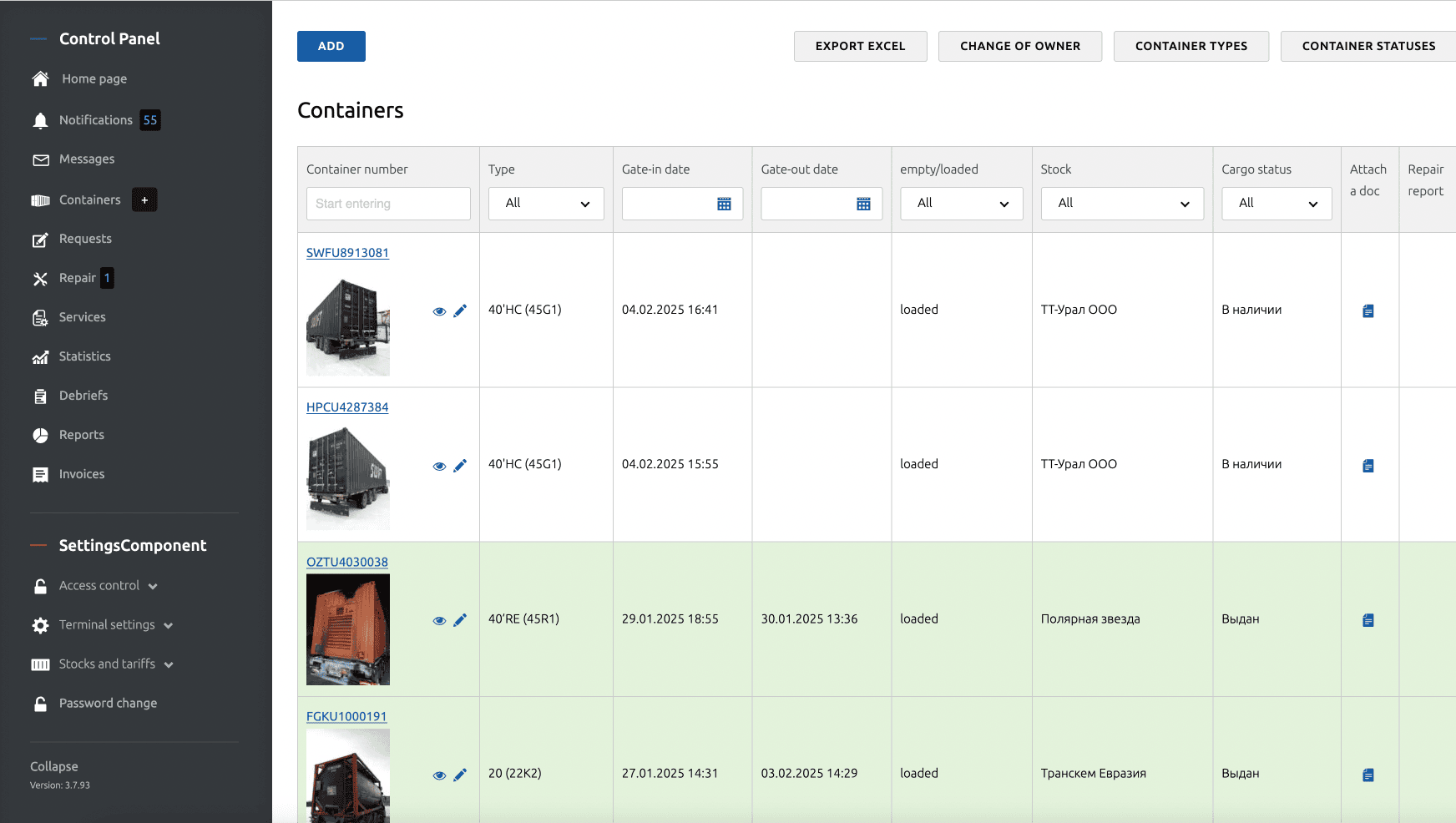

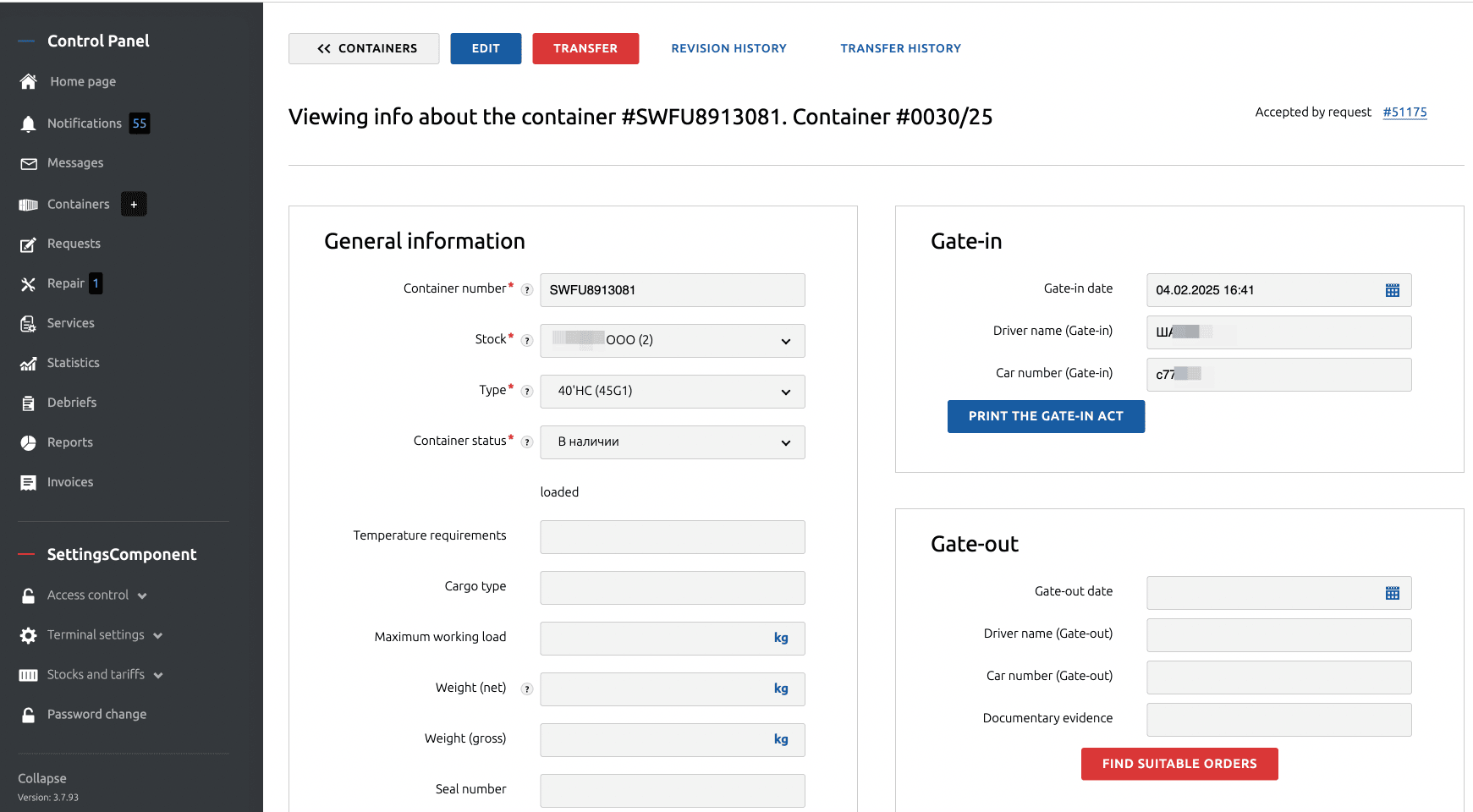

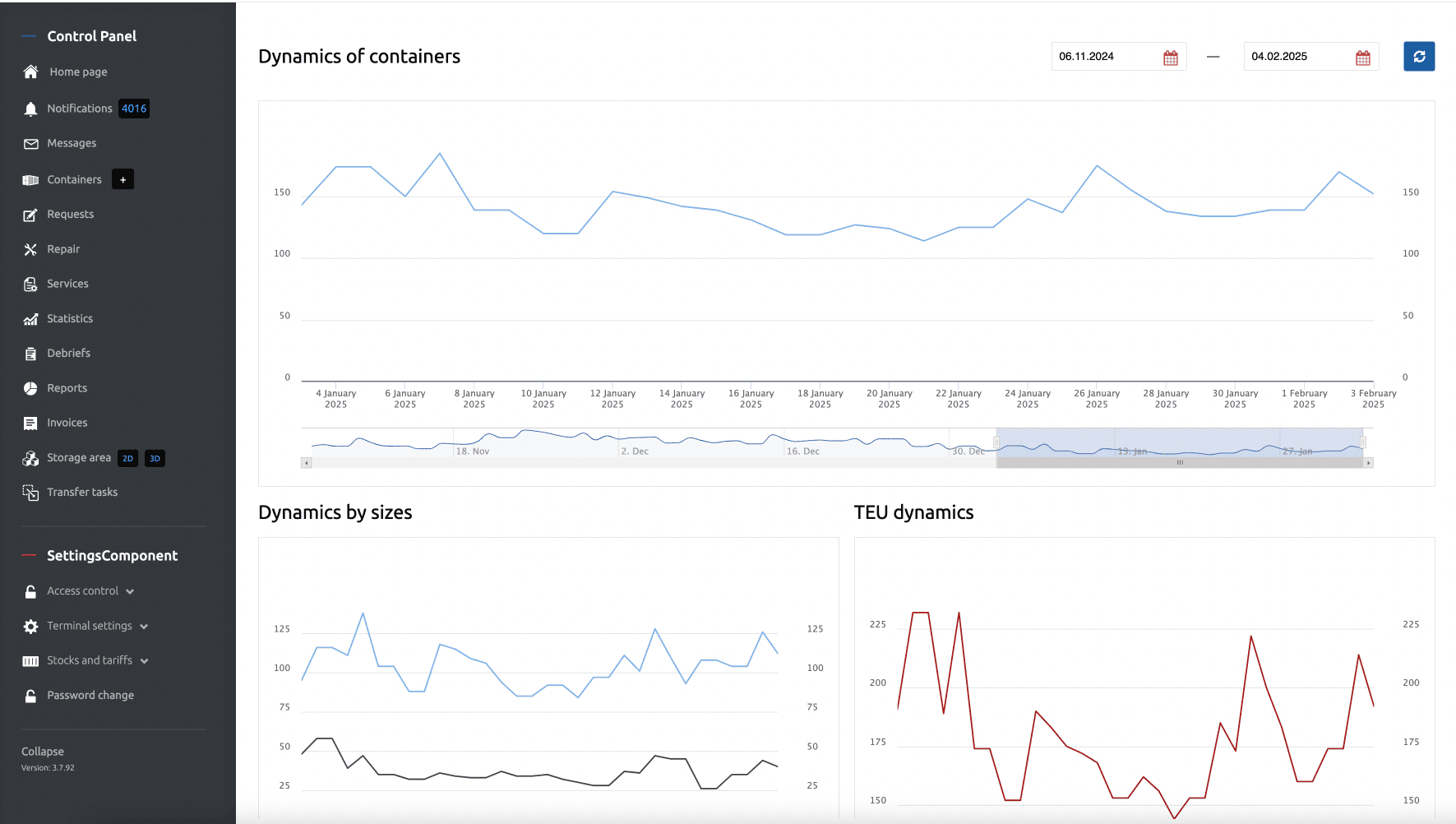

LogProfit is a container management platform that delivers a complete suite of tools and modules designed to deploy and manage operations with unmatched real time visibility. As a container based solution hosted the cloud, LogProfit empowers container terminals, depots, and yard operations by integrating advanced container orchestration and orchestration platform capabilities. It supports seamless yard operations and container handling with the management system that adapts to your business needs, ensuring efficiency and precision in every process.

Handling over 90% of global trade through the sea, LogProfit ensures that terminals process data with real time visibility and precision. This system collects, analyzes, and stores essential information for container movement while integrating flawlessly with existing terminal operating system infrastructures. Its design is container based and supports containerized applications to boost operational performance, efficiency and promote scaling and smooth workflows, meeting the highest standards of the industry.

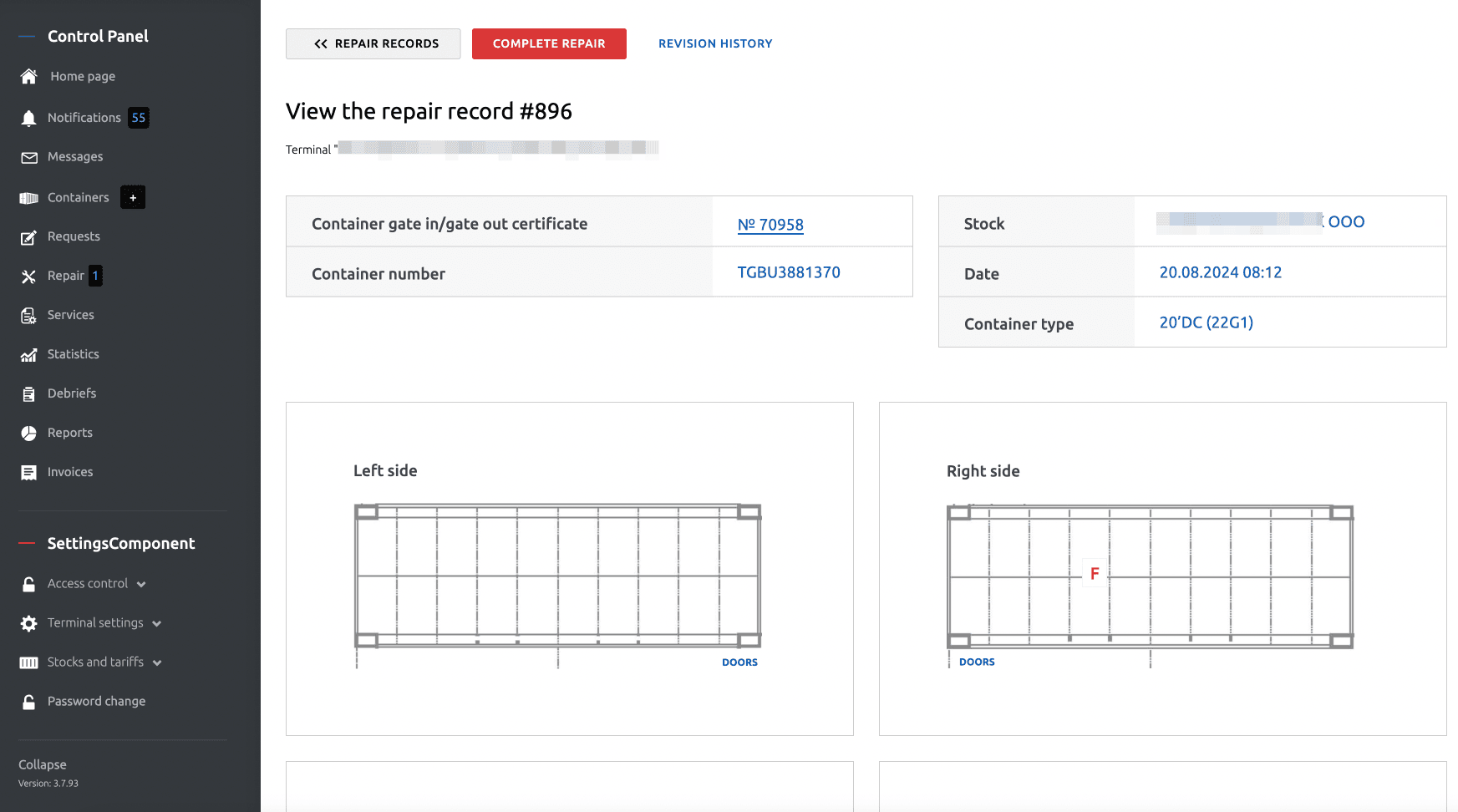

Leveraging a unified database in the cloud, LogProfit ensures your data is accessible and secure, meeting rigorous compliance standards while providing robust security and performance updates. Terminal staff you can connect via wireless RF terminals and specialized networks to monitor operations, ensuring that your container assets are managed effectively and your yard remains optimized. The system offers a new way to streamline maintenance and repair scheduling while facilitating effective management and deployment of resources.

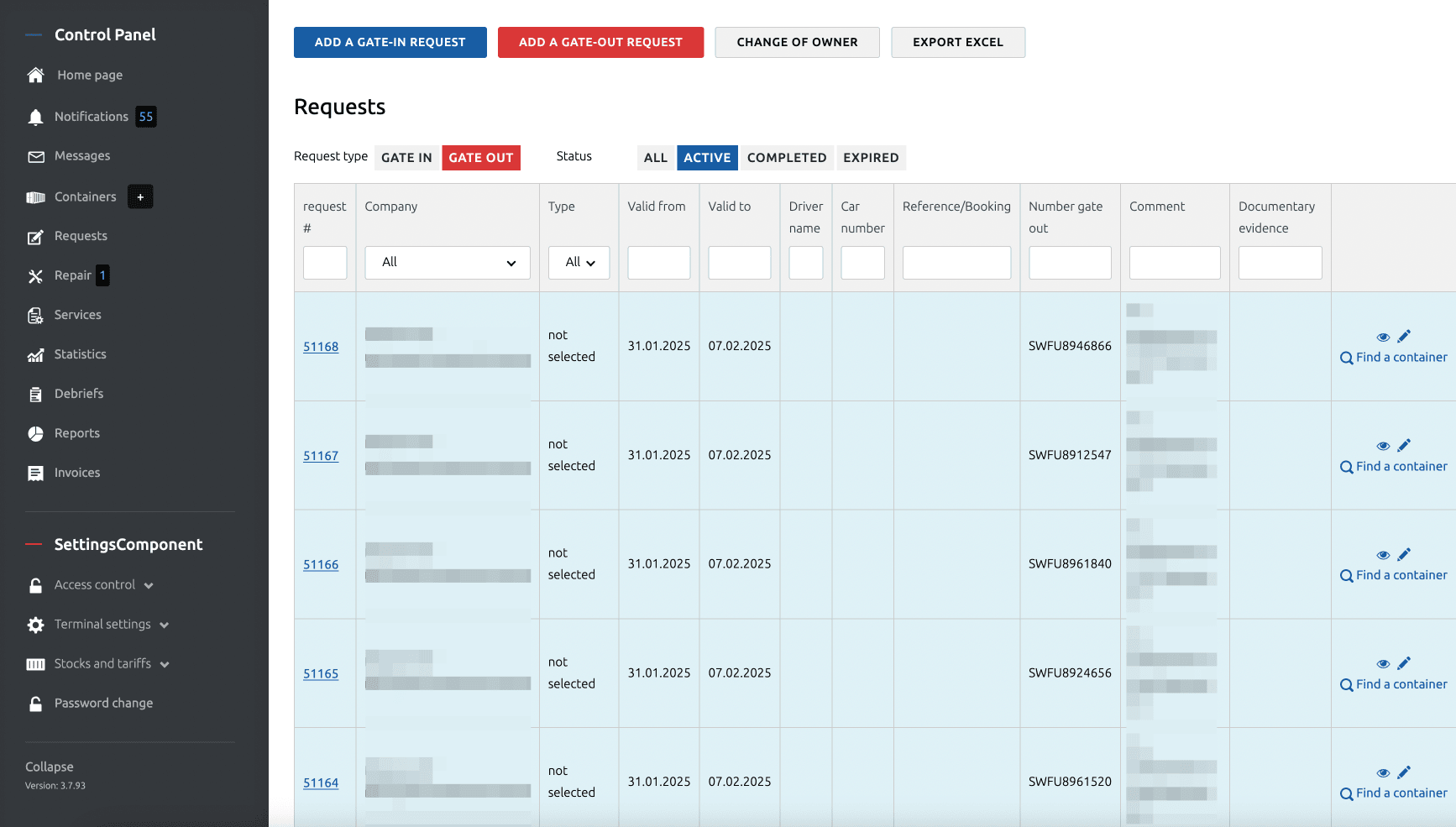

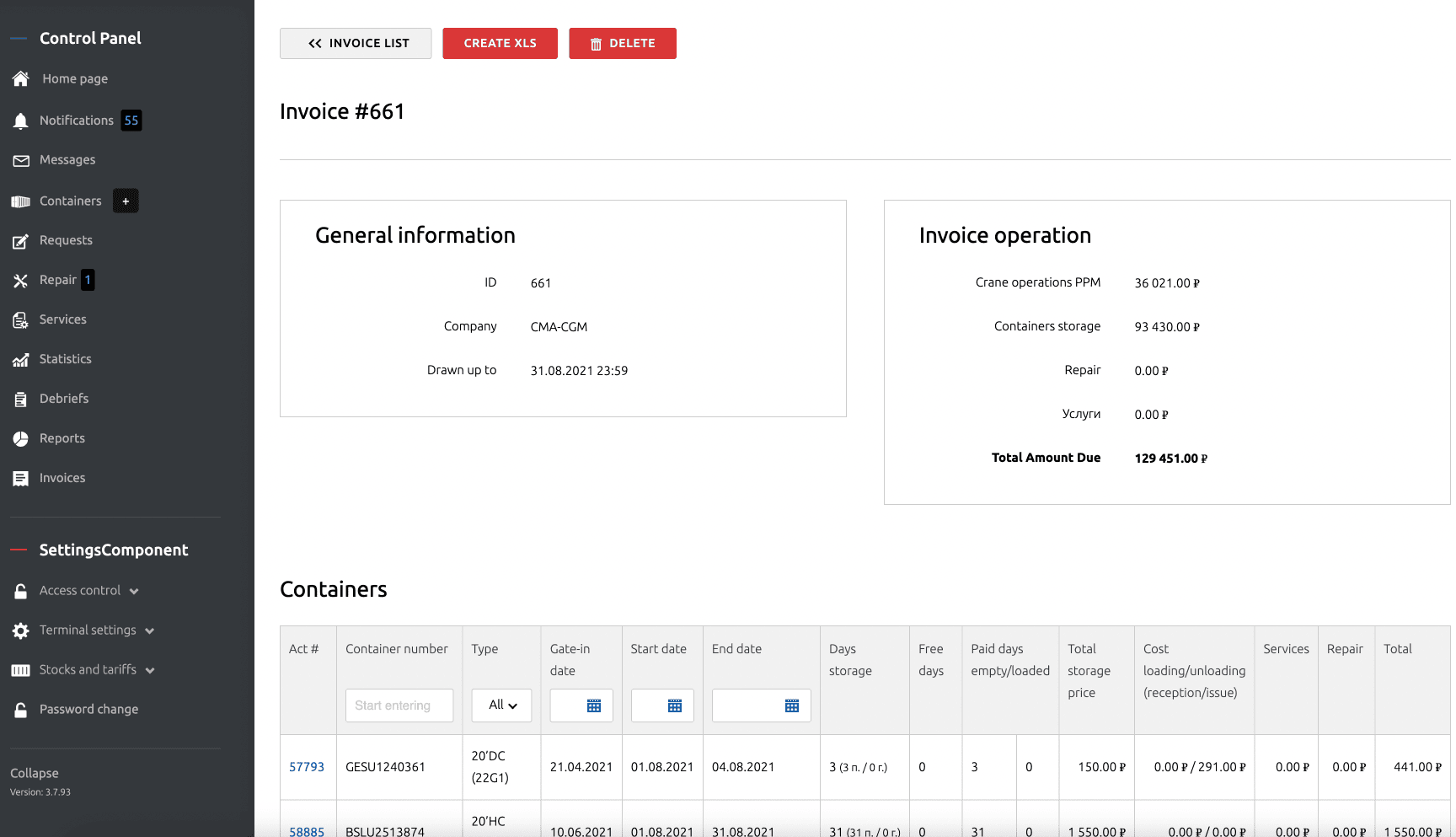

LogProfit isn’t just about data storage – it transforms depot, yard, and terminal operations. It manages inbound and outbound processes, schedules maintenance, and optimizes transport logistics. With LogProfit, experience a robust ecosystem where you can run advanced analytics, try innovative api integrations, and achieve superior performance. This platform helps you tackle various challenges in the logistics ecosystem through effective automation and continuous updates.

Designed as a comprehensive container management platform, LogProfit integrates seamlessly with existing systems, ensuring real time visibility into every process. It supports open source connectivity and advanced tracking, making it indispensable in today’s competitive supply chain environment where applications and integration are key.

| Plan | Price (per month) | User Access | Average TEU per Day | Key Features |

|---|---|---|---|---|

| Starter | $250 | Up to 10 | Up to 20 TEU | Core features: container tracking, document printing, repair module, financial module, access management, multilingual support, data encryption. |

| Elementary | $500 | Based on Agreement | Up to 50 TEU | All Starter features plus automated billing, 2D/3D address mapping. |

| Base | $750 | Unlimited | Up to 100 TEU | All Elementary features plus EDI data exchange, database import (Excel, XML, CSV), train formation, personnel training. |

| Advanced | $1000 | Unlimited | Up to 150 TEU | All Base features plus API integration, extended trial period, 10 development hours per month. |

| Advanced Plus | Custom Pricing | Unlimited | 150+ TEU | All Advanced features plus tailored solutions, third‑party system integration, custom reporting, analytics. |

| Service / Option | Description |

|---|---|

| Extra TEU Limit | +$50 for every additional 20 TEU per day. |

| API Integration | Included in Advanced pricing or $150/month separately. |

| Additional Development Hours | $50/hour. |

| Personnel Training | $500 (one‑time fee). |

| EDI Synchronisation with One Carrier | $100/month (e.g. CMA CGM, Maersk, etc.). |

For further technical information or to discuss your specific requirements please contact our support team.

???? Start with a 7‑day free trial on any plan when subscribing for a year! ????

Авторизация

Registration