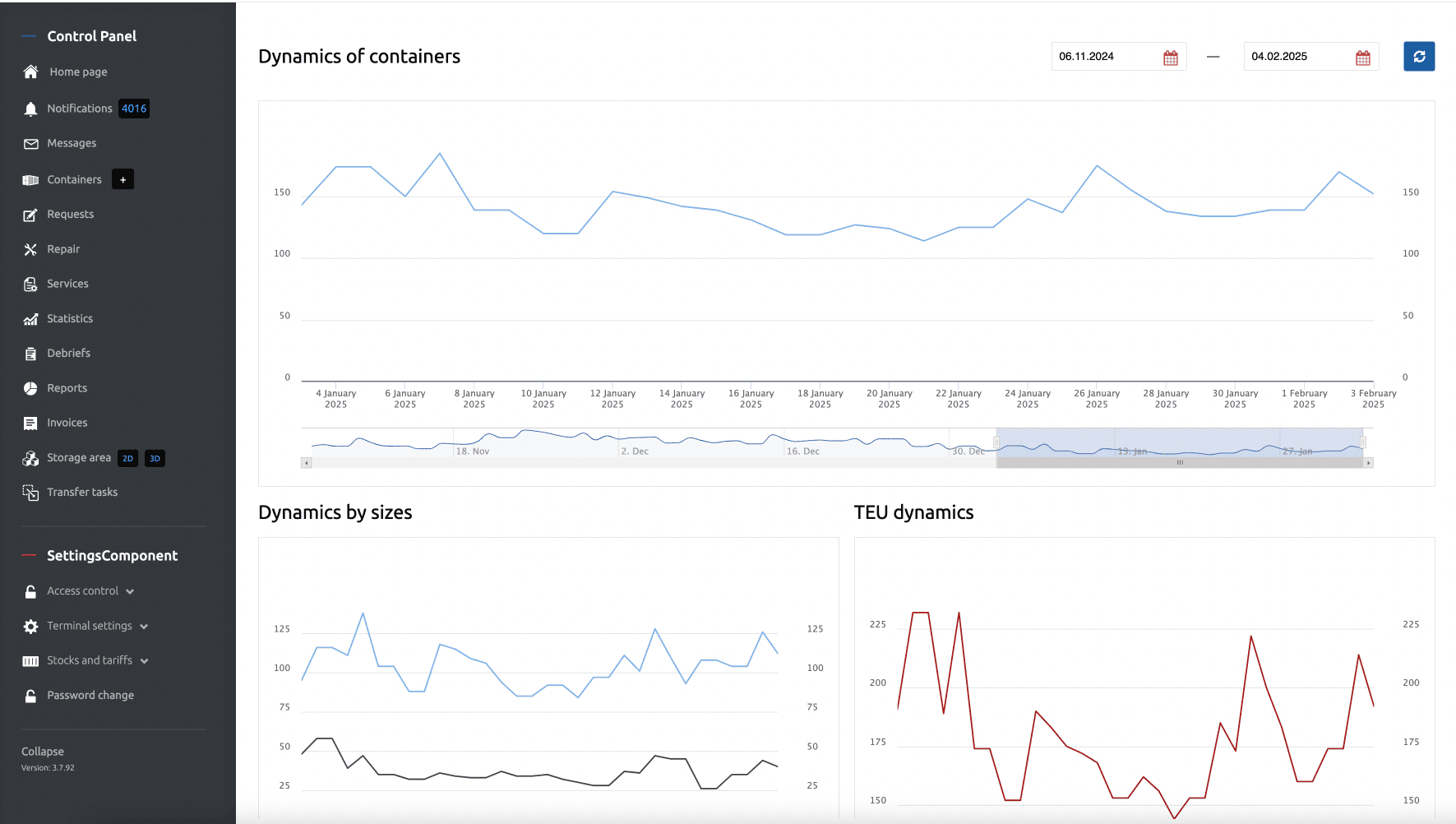

LogProfit is a cutting‑edge solution designed to reduce costs, increase efficiency while streamlining operations for container facilities. Gain full control over day‑to‑day activities; optimise key operations (gate‑in / gate‑out / loading) at inland depots, ports and rail hubs. Our intuitive interface boosts productivity; it enables seamless cargo movement using advanced container equipment such as Loaded, Empty, Reefers, Tank Containers, Reach stackers, Truck Scheduling, Works Scheduling, Carrier Bookings, OCR, 3D visualisation online, 2D‑map zone planning and inventory management. All data is securely stored in a cloud‑based application that ensures real‑time tracking, automation, seamless connectivity; it addresses maintenance plus repair needs while meeting custom requirements.

Container facilities, yards, depots leverage our depot management system to remain competitive while maximising revenue. Shipping lines handle 90% of global trade; thus, automation, real‑time tracking, seamless integration are imperative. LogProfit helps companies reduce unnecessary expenses; it accelerates processing, enhances cargo tracking. Experience new features that empower you to manage your operations at the next level. Enjoy quick integration, a number of advanced functionalities plus more from initial entry to final exit.

Our DMS is an automation‑driven software solution for shipping companies. This container terminal software optimises turnaround time, increases operational efficiency, minimises manual errors. The automated system manages movement, tracking, freight scheduling; it eliminates errors, delays. It provides seamless EDI integration between facilities; this improves real‑time data visibility, overall efficiency and ensures precise location tracking to support various industries.

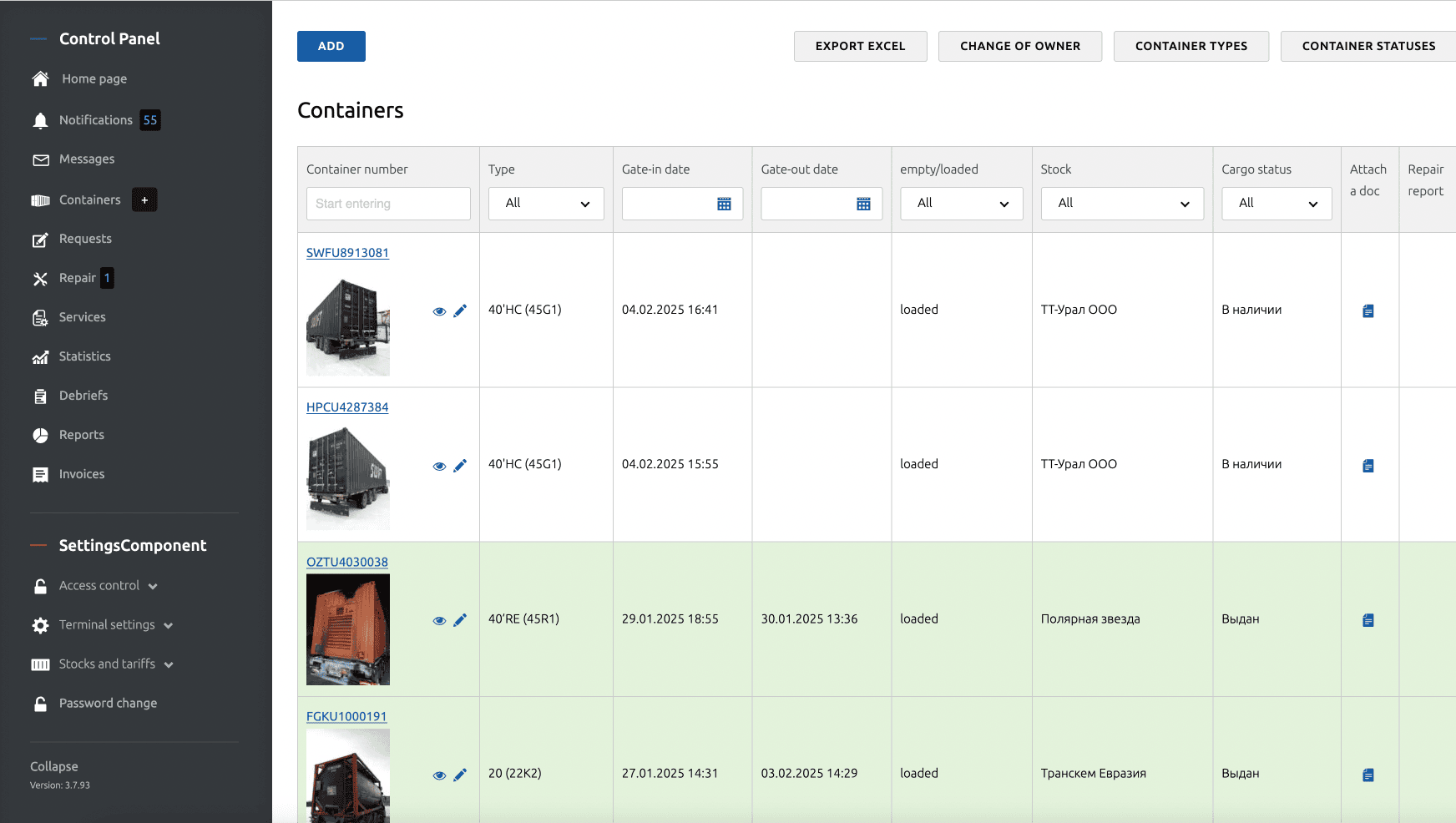

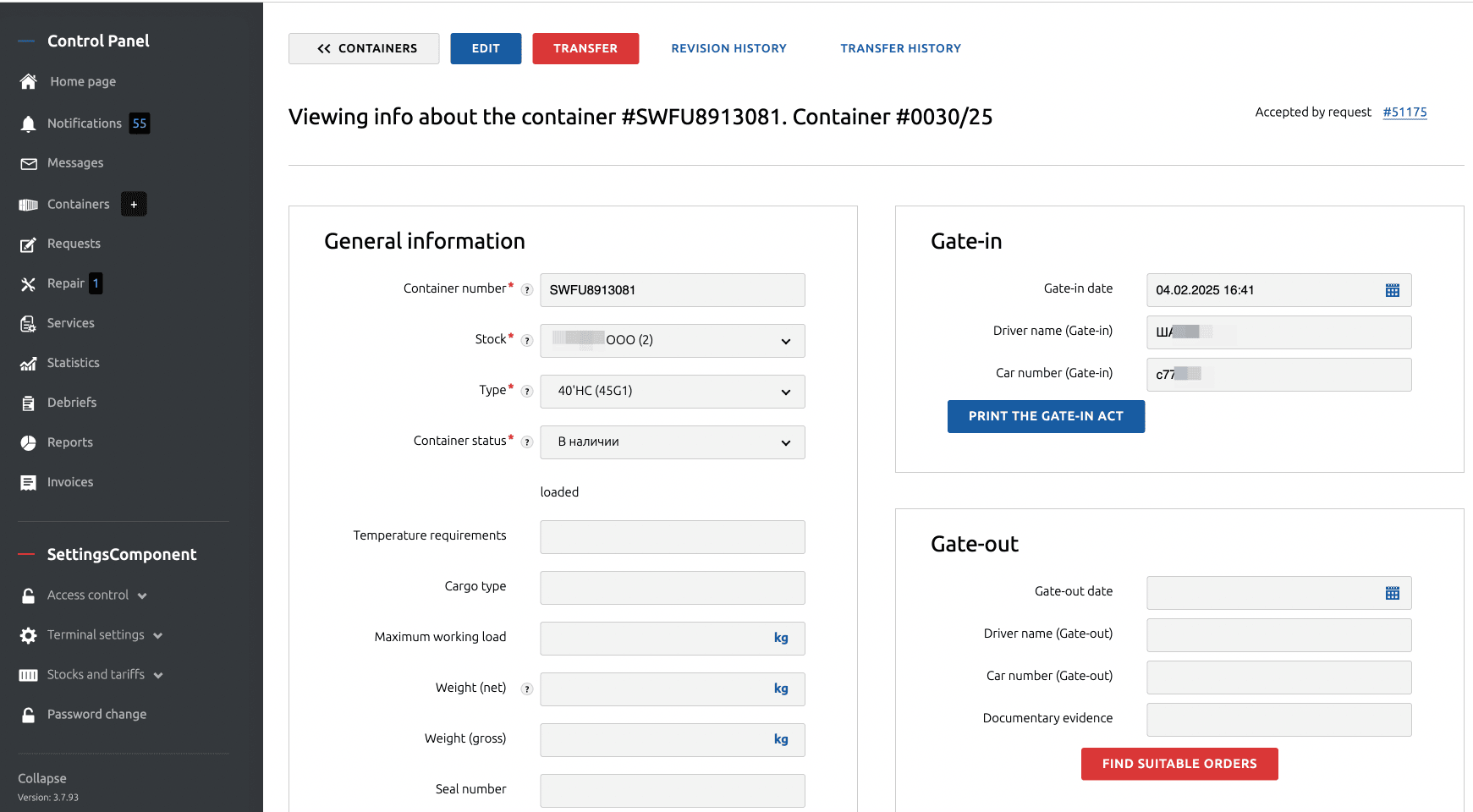

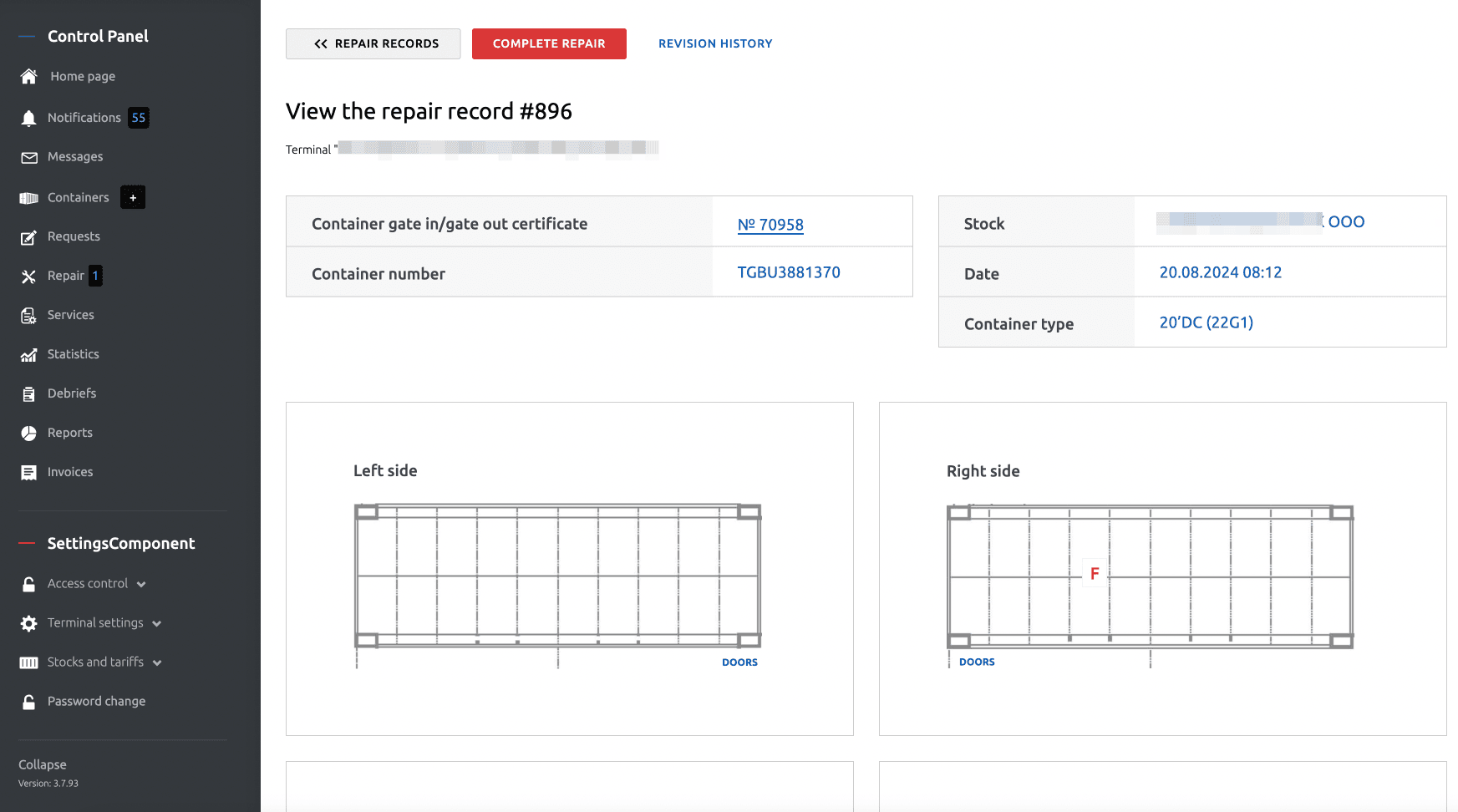

Our systems evolve with leading technology and logistics innovations. A yard management system streamlines workflows while enhancing inventory tracking, container scheduling, freight handling. A terminal automates depot, cargo operations; it accelerates processing, monitoring, data management. LogProfit transforms depots into high‑performance hubs that ensure faster turnaround, real‑time shipment tracking, automated invoicing. Additional detailed information supports maintenance plus repair protocols; all operations meet your stringent requirements.

???? Get started today!

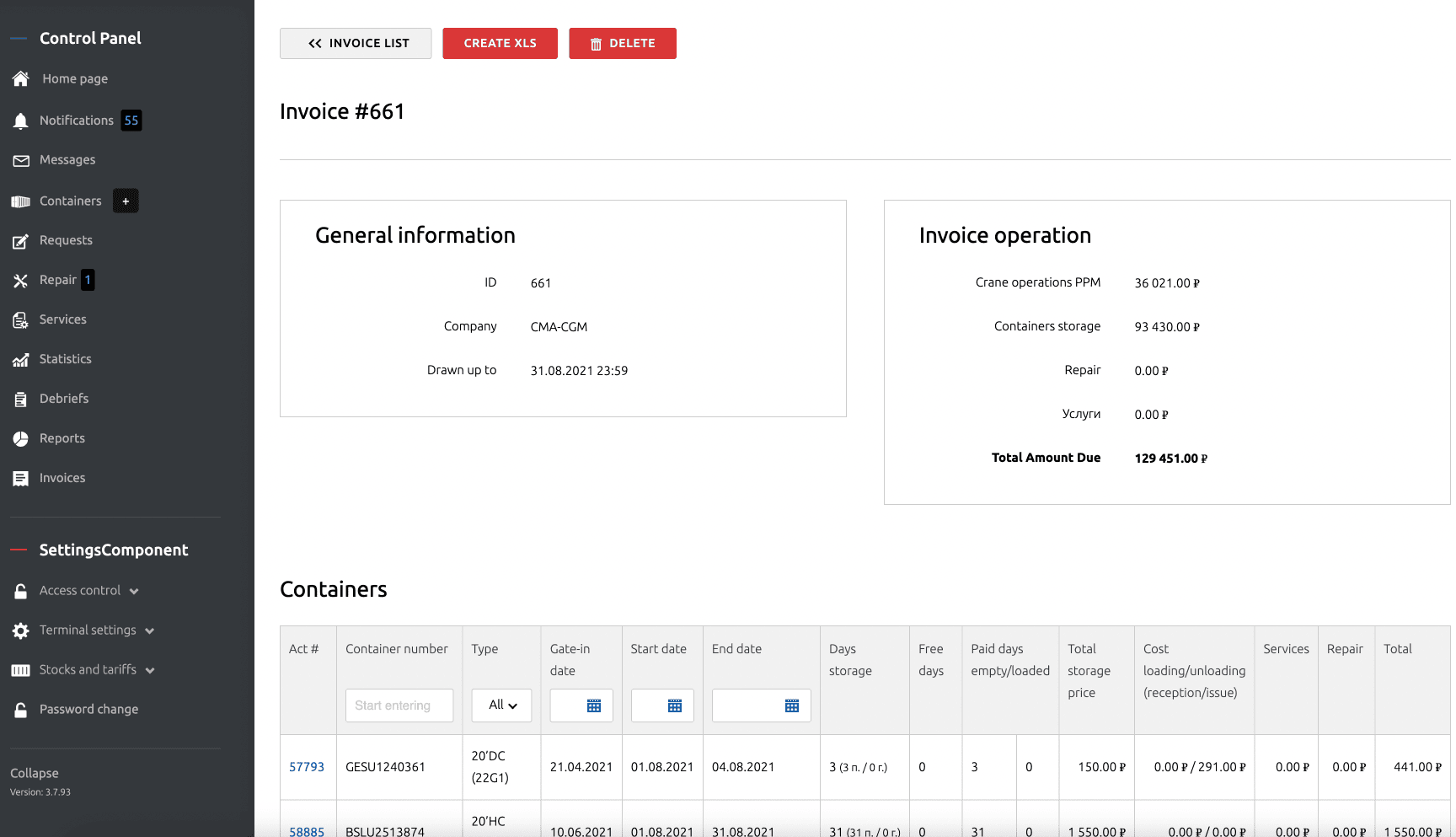

A container accounting software system simplifies billing, reporting, and financial tracking for container facilities and warehousing. It provides transparent services that help businesses eliminate errors, optimise cash flow. Real‑time tracking with EDI integration allows users to monitor transport status, track shipments, and automate financial processes; this ensures quick resolution of issues and effective system maintenance.

| # | Functionality |

|---|---|

| 1 | Auto charge calculations for Entry, Handling, Daily/Weekly Storage. |

| 2 | Repairs [M&R] include scheduling, miscellaneous costs, estimates, billing, reefer service, cleaning, profitability plus stock control. |

| 3 | Multi Depot, Multi Cost Centre, Multi Country. |

| 4 | Warehouse management. |

| 5 | Multi‑language support & localisation. |

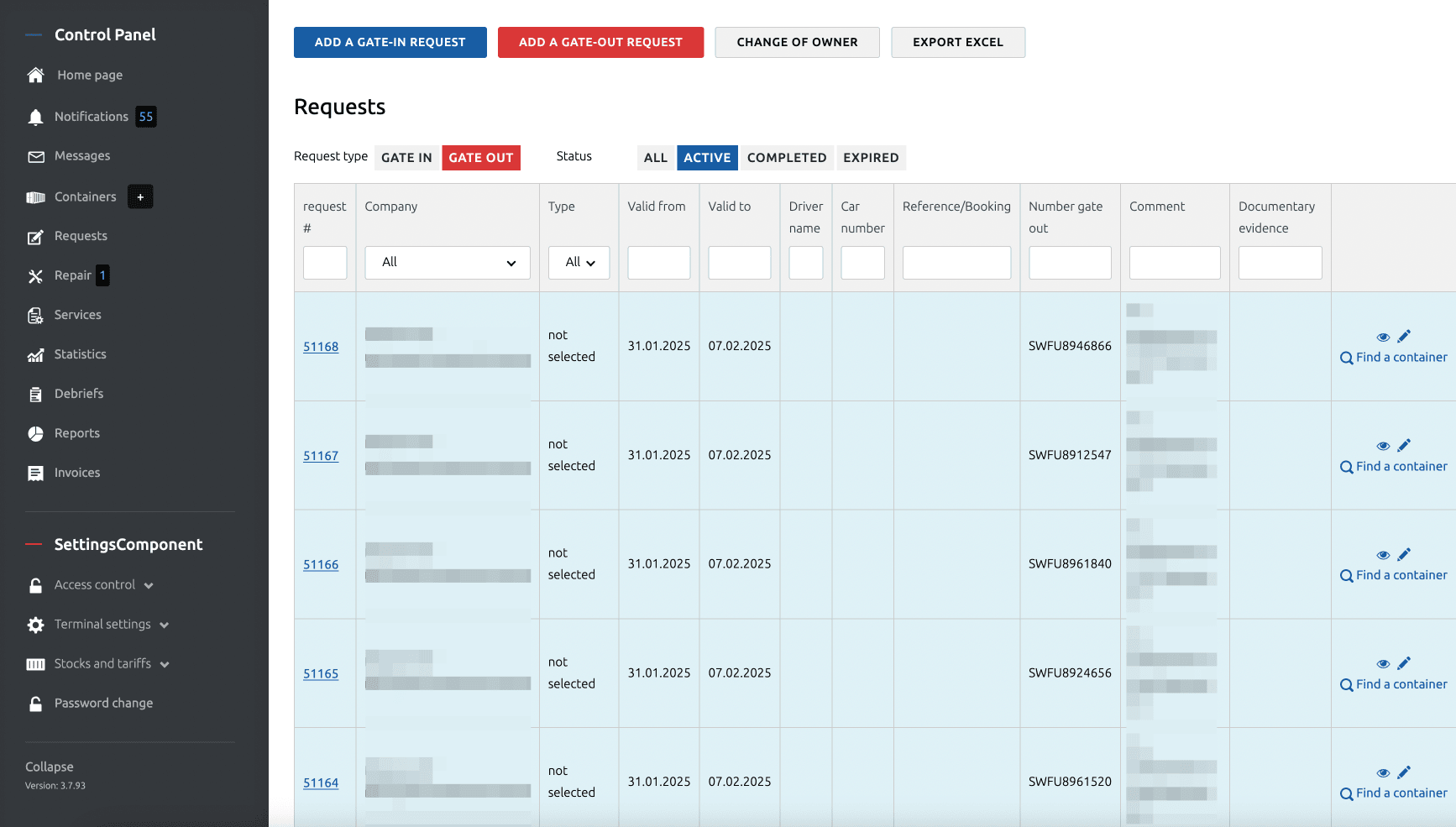

| 6 | Yard management & dispatching process. |

| 7 | Full container & transaction history – detailed drilldown, damage history, inspections. |

| 8 | Detailed Reporting – revenue graphs, export to Excel, PDF or Email. |

| 9 | EDI Integration – import/export any EDI files for easy data processing. |

| 10 | Real‑time Container Status – online status enquiries, release requests. |

| 11 | Transport Operations, Arrival Scheduling (Vehicle, Vessels, Rail). |

| Plan | Price (per month) | User Access | Average TEU per Day | Key Features |

|---|---|---|---|---|

| Starter | $250 | Up to 10 | Up to 20 TEU | Core features: container tracking, document printing, repair module, financial module, access management, multilingual support, data encryption. |

| Elementary | $500 | Based on Agreement | Up to 50 TEU | All Starter features plus automated billing, 2D/3D address mapping. |

| Base | $750 | Unlimited | Up to 100 TEU | All Elementary features plus EDI data exchange, database import (Excel, XML, CSV), train formation, personnel training. |

| Advanced | $1000 | Unlimited | Up to 150 TEU | All Base features plus API integration, extended trial period, 10 development hours per month. |

| Advanced Plus | Custom Pricing | Unlimited | 150+ TEU | All Advanced features plus tailored solutions, third‑party system integration, custom reporting, analytics. |

| Service / Option | Description |

|---|---|

| Extra TEU Limit | +$50 for every additional 20 TEU per day. |

| API Integration | Included in Advanced pricing or $150/month separately. |

| Additional Development Hours | $50/hour. |

| Personnel Training | $500 (one‑time fee). |

| EDI Synchronisation with One Carrier | $100/month (e.g. CMA CGM, Maersk, etc.). |

For further technical information or to discuss your specific requirements please contact our support team.

???? Start with a 7‑day free trial on any plan when subscribing for a year! ????

Авторизация

Registration